Challenge us

We are ready to compete and prove ourselves in your packaging issues.

Our plastic caps & dispensing closures product line offers endless possibilities to close a bottle or container, thus keeping its content safe.

Screw caps are available in two standard sizes according to standard threading or with custom dimensions for any neck finish styles. We manufacture non-tamper evident screw caps for a variety of industries.

Most frequently used in the FMCG sector, tamper evident screw caps protect a product’s integrity on the shelf by assuring the consumer that it has not been opened before. Any standard or custom-designed plastic caps can be manufactured with an additional sealing ring.

We offer dispensing closures for products of different viscosities with both simple and complex designs with in-line inserted valves.

Self-sealing plastic caps feature an additional cone that is molded with the cap, thus providing a cost-effective solution for an exact-fit closure.

Ijection molded caps for bottles are ideal for a variety of bottled products, induction seal liners prevent leaks, preserve perishable products and may act as tamper evidence. Insertion of induction seal liners are into the cap is an in-line automated process.

Ideal for dispensing a variety of viscous material, flip-top or snap-on caps allow the user to reseal the content after its initial use. Active hinges are more durable and user friendly, therefore, they are recommended when the product will be resealed multiple times.

Flip-top or snap-on dispensing cans with inactive hinges feature a lighter hinge. It’s an ideal solution if the user is expected to want to remove the plastic cap or in case of a limited budget.

We manufacture aerosol caps with different profiles, heights, corner radius to fit any custom-made spray head and protect the valve. Light-weight design allows for saving on polymer usage, thus reducing both manufacturing and logistics costs.

Both standard and custom-designed plastic caps can fit any inserts for special applications such as drippers, nozzles, different applicators - most frequently used in the medical and pharmaceutical industry.

Our standard plastic caps and dispensing closures come in different sizes, however, we offer custom-designed plastic caps for all use cases to ensure a tight fit for your exact product. Plastic caps can be manufactured in any RAL colour and can have a plain or ribbed style, depending on the need for your packaging solution.

We can accommodate the need for private label caps, as well. Our tooling design allows for including an exchangeable part into the tool with the company’s logo.

Dispensing closures can be supplied as a single component or pre-assembled, depending on the requirements of your manufacturing processes.

We rely on cube molding technology when we need to scale the production of a product fast. With 2 x 64-cavity molds, we can manufacture several tens of millions of a product in a year. If mass production is needed, we automate as much as possible of the production process in order to maximise efficiency: production of a 2-component product in two steps, closure of a flip-top cap and testing.

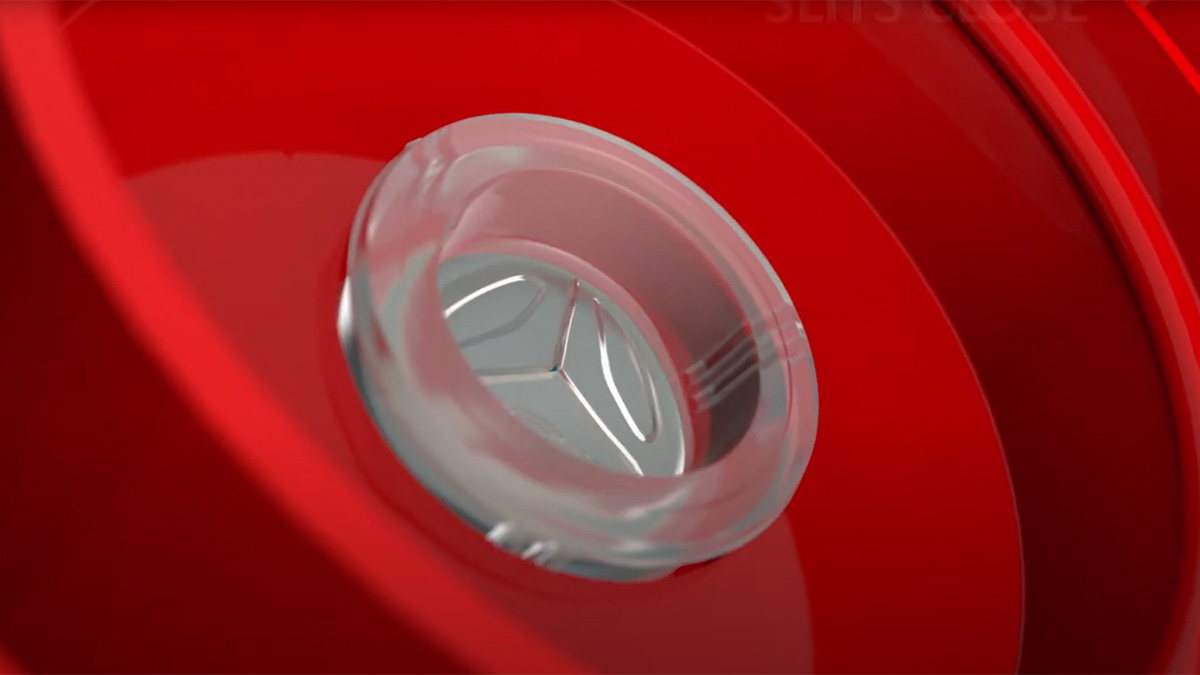

We are proud to introduce our custom-designed MikaTech StarTech Flexible Valve, a new type of flexible dispensing valve for dispensing a wide variety of viscous materials. This low-cost, yet premium feature is as effective, but significantly cheaper than alternative silicone-based designs. The MS Flexible Valve is a two component system that is produced without silicone.

Flexibility of the dispensing valves allows for use for a variety of materials, therefore, we not only recommend this solution for sauces such as ketchup or mayo, but any dispensing use case where drip-free dosage is important. Depending on the viscosity of the material, we can adjust the hardness of the valve. Pre-molded slits guarantee tight fit into any bottle.

Given the initial use case, the MS Flexible Valve is suitable for use in the food industry, but it offers a viable solution for the packaging of chemicals, as well.

We are ready to compete and prove ourselves in your packaging issues.