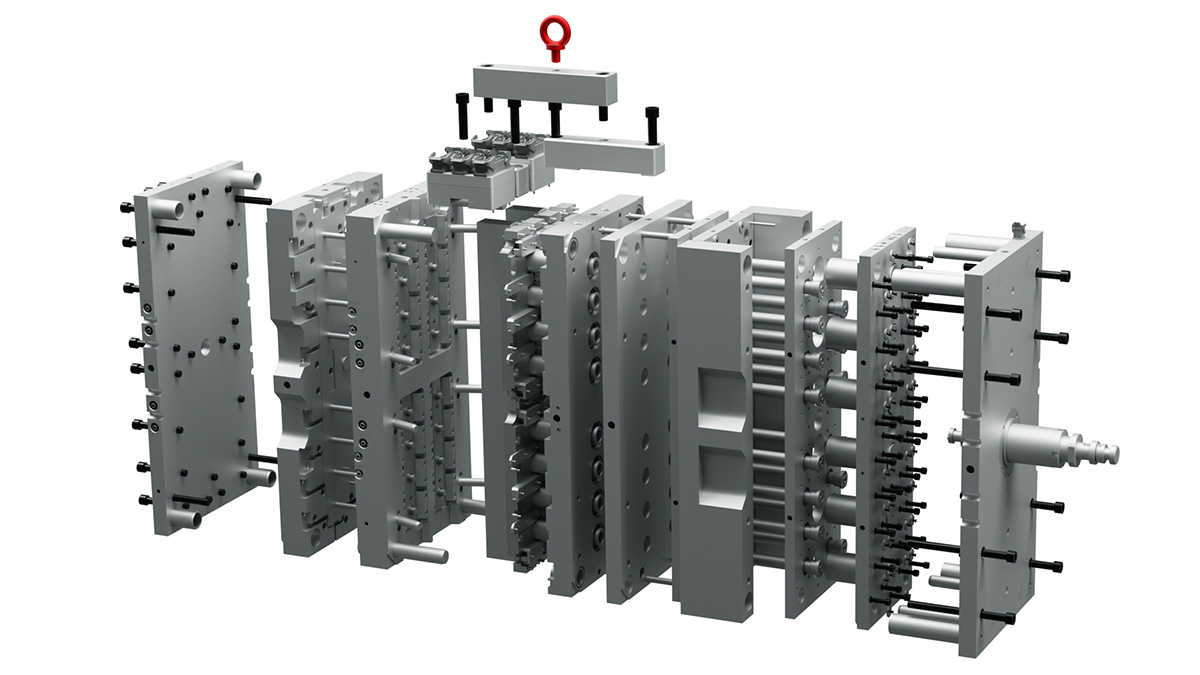

High-quality moulded plastic components can only be produced with perfect tools

The portfolio of the toolshop includes both the production of prototype and pilot tools required during product development, and the fabrication of tools intended for series production, as well as the maintenance and repair of existing tools and parts.